Mx Specs: Aluminum Material

ALUMINUM MATERIAL

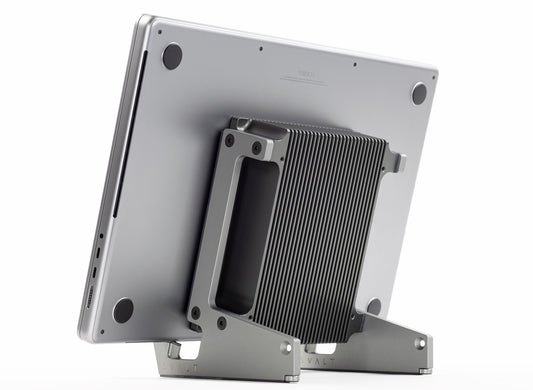

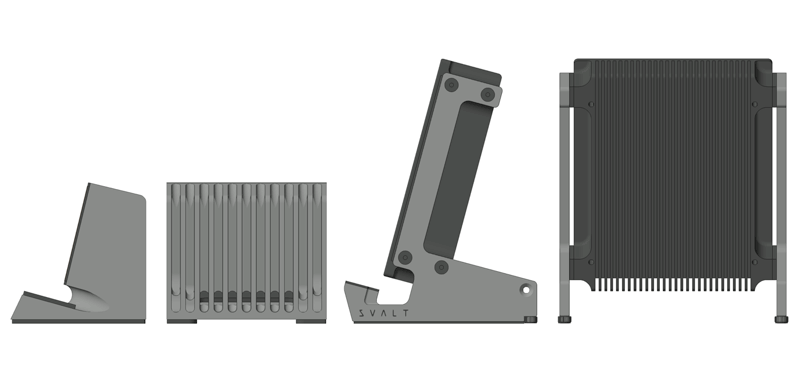

Material Description: Supports and heatsink milled from solid 6061-T6 aluminum bar stock.

Available Finishes / Colors for Supports: The aluminum supports are available with the following finish/color options:

- Space Black Anodize: A dark gray anodize with bead-blasted surface similar to Apple’s Space Black finish available on MacBook Pros from 2023+.

- Space Gray Anodize: A gray anodize with bead-blasted surface similar to Apple’s Space Gray finish available on MacBook Pros from 2016 to 2023 and MacBook Airs from 2018+.

- Silver Anodize: A clear anodize with light gray color and with bead-blasted surface similar to Apple’s Silver finish available on all Mac laptops.

- Raw Aluminum: Raw aluminum with hand and mill finish surfaces have a mildly bright “silver” like appearance.

Available Finishes / Colors for Heatsink: The aluminum heatsink is available with the following finish/color options:

- Space Black Anodize: A dark gray anodized aluminum with hand and mill finish surfaces similar to Apple’s Space Black finish available on MacBook Pros from 2023+.

- Raw Aluminum: Raw aluminum with hand and mill finish surfaces have a mildly bright “silver” like appearance.

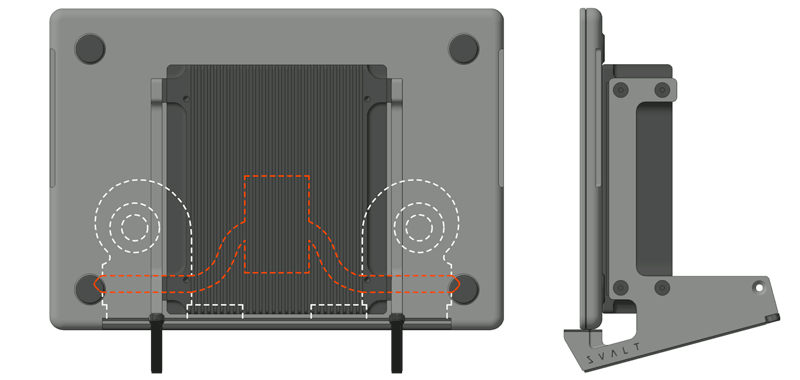

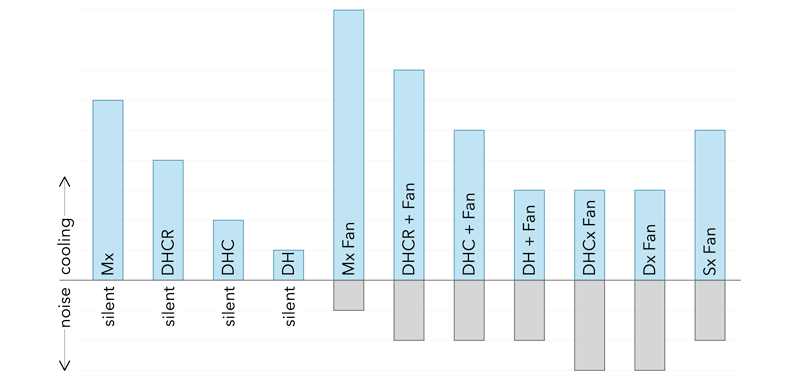

Cooling Performance for Heatsink: The heatsink with space black anodize aluminum finish has a slight improvement in emissivity cooling compared to the heatsink with raw aluminum finish. This is only a slight improvement that is most apparent with passive airflow cooling, and is less notable when a fan is added to provide active airflow cooling. For the supports, there is no different in cooling performance between raw and anodized aluminum.

Surface Condition for Raw Supports: The flat face surfaces are hand finished to remove more significant and noticeable milling marks, but are otherwise left with a raw aluminum surface condition.

Surface Condition for Anodized Supports: The flat face surfaces are hand finished to remove more significant and noticeable milling marks, and then all surfaces are bead-blasted to create a more even surface condition. Threaded holes in the middle of the bottom edge are used for anodize racking. The anodize process can leave some discoloration at the racking holes. The bottom pads cover the racking holes and discoloration, however, a slight amount of discoloration may still be visible near the bottom pad.

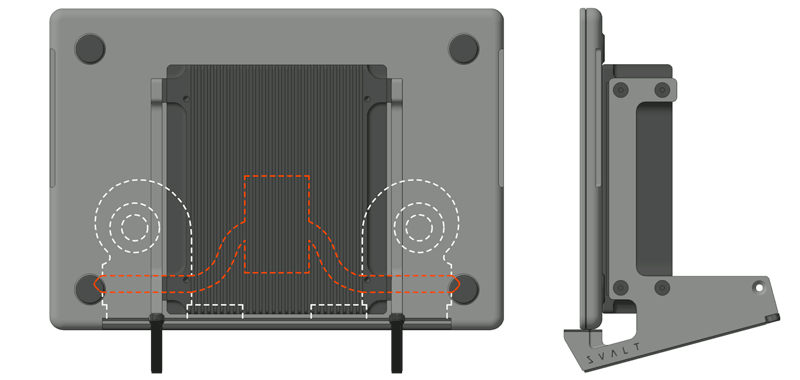

Surface Condition for Raw / Anodized Heatsink: The top coupling plate of the heatsink is hand finished to create an extra smooth and flat surface for maximum heatsink cooling performance. The rest of the heatsink has a CNC machined / milled finish. The interior walls of the cooling fins and cooling fin channels may have a slightly rougher machined finish as the result of fabricating the incredibly thin cooling fin and incredibly narrow cooling channels required to achieve the exceptionally high levels of cooling surface area within a heatsink made from a solid block of aluminum.

Surface Finish for Raw Aluminum Supports / Heatsink: Raw aluminum is a strong and enduring material that is naturally resistant to corrosion and does not “rust” like steel. Raw aluminum is inherently stable as the surface forms a thin and protective layer of oxide on the surface when exposed to air, which is a natural type of anodize finish that helps prevent further corrosion. The surface appearance will patina and change over time as a result of this oxidization process, as well as reacting to sunlight, moisture, fingerprints, and other factors.

Surface Finish for Anodized Aluminum Supports / Heatsink: An anodize finish applied to the raw aluminum increases the thickness of the aluminum’s natural oxide layer, making it more resistant to wear, scratches, and corrosion. The anodize process includes a dye, sealant and other steps to improve appearance and durability.

Care for Raw Aluminum Supports / Heatsink: Keep raw aluminum dry. When handling the heatsink’s top surface laptop coupling plate care should be taken to prevent scratches and exposure to substances that can leave a mark, including finger prints. Surface scratches, marks or other changes to the cosmetic surface may occur over time. Customers may prefer the patina and “weathered” surface appearance, or they can recondition and brighten surfaces as desired. With proper care aluminum can endure for decades and centuries.

Cleaning and Reconditioning Raw Aluminum Supports / Heatsink: Wipe surface with a soft cloth or sponge that is dampened with warm water. Add a mild dish soap if needed. Additional steps can be used to clean and/or recondition raw aluminum surfaces, including polishing with a polishing product made specifically for use with raw aluminum. Additional steps can be taken as needed to restore or repair, such wet sanding with a fine grain sand paper. Make sure to fully dry raw aluminum with a soft towel and then leave surfaces uncovered to air dry after any cleaning or restoration.

Cleaning Anodized Aluminum Supports / Heatsink: Wipe surface with a soft cloth or sponge that is dampened with warm water. Add a mild dish soap if needed.

Warning: Do not use chemical cleaners, solvents or other substances unless they are specially designed for use with raw or anodized aluminum. Avoid exposing pad adhesive to moisture.

Featured Products

-

Cooling Dock MxDW

Regular price From $309.00 USDRegular priceUnit price / per -

Cooling Dock MxD

Regular price From $409.00 USDRegular priceUnit price / per -

Cooling Stand MxSW-hi

Regular price From $319.00 USDRegular priceUnit price / per -

Cooling Stand MxS-hi

Regular price From $419.00 USDRegular priceUnit price / per -

Cooling Stand MxSW-lo

Regular price From $299.00 USDRegular priceUnit price / per -

Cooling Stand MxS-lo

Regular price From $399.00 USDRegular priceUnit price / per -

Cooling Stand Sx

Regular price From $279.00 USDRegular priceUnit price / per -

Cooling Stand SxM

Regular price From $279.00 USDRegular priceUnit price / per

Product Selection Guides

-

Compare

CompareCompare product features and specifications.

-

Laptops

LaptopsRecommended products for your laptop model.

-

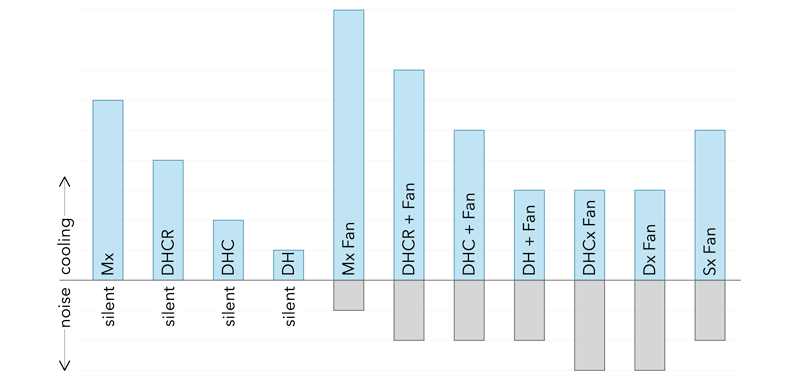

Performance

PerformancePerformance testing with a variety of laptops.

Product User Guides

-

Product Upgrades

Learn about available product upgrades.

-

Right-to-Repair

Learn how to install modular components.

-

Product Setup

Learn how to setup and operate products.

Cooling Stand

“ProTools would normally have the Apple fans screaming… using it on the low setting and it's doing a beautiful job of keeping quiet… appreciate the design, skill and care that went into this product.” - L. B.

Cooling Dock

“We’re pushing them day-in and day-out. Heavy imaging, editing, rendering… Some days it was like they were literally cooking. But no more! Our Svalt D's keep them chill and lets us use them like true workstations.” - K. J.

Cooling Stand

“Respect! For sure it clearly shows your approach to design, material and sustainability. Great product. Fan noise is not audible on the low setting. Perfect! Thanks a lot for the great product.” - J. J.

Cooling Dock

“I’ve used a Hengedock for years, had no idea it was blocking one of the fans… Wish I had this cooling dock since I started using external monitors. I’m running between 13-25 cooler… benchmarks are even better.” - R. S.

Cooling Stand

“There is a noticeable help with thermals as the computer's temperature is substantially better. The fan is extremely quiet in its low setting and exceedingly efficient in its highest one. I absolutely love it.” - J. R.