ABOUT

About Company

MeaningThe name SVALT is derived from the French word “svelte,” meaning graceful & elegant, and the Swedish word “sval,” meaning elegant & cool.

Founding

SVALT was founded in 2011 by Chad Kirkpatrick as a mission driven product design studio after a 15 year architecture career focused on sustainability, passive heating/cooling, and responsive design. “My goal with SVALT is to make the best products that I can; products that are as much art as tech, and as much objects of substance as machines engineered for performance. This focus allows me to drill down into the hyper-niche where I can pursue the most extreme designs and obsess over the smallest details to create high-end products for professionals and others that demand the most from themselves and their equipment.” This approach has helped SVALT create numerous first-of-kind and best-in-class products with a wide set of features unique within the market, while Chad’s lifelong focus on sustainability drives him to push boundaries within the consumer electronics market.

About Sustainability

PurposeFor SVALT, sustainability is about creating systems that support the health of our global human community and our planet’s natural ecosystem through the more efficient use and the more equitable distribution of our planet’s limited resources. This approach reduces consumption and waste byproducts, while bringing us into closer community with others; a community where we directly benefit from the well-being of others.

Reduce + Reuse + Recycle

Reduce, Reuse and Recycle are the three R’s of sustainability, and are core to Chad’s worldview and his work through SVALT as outlined in the following sections. Reduce is considered to have the most benefit, followed by Reuse, and then Recycle is the last option to pursue.

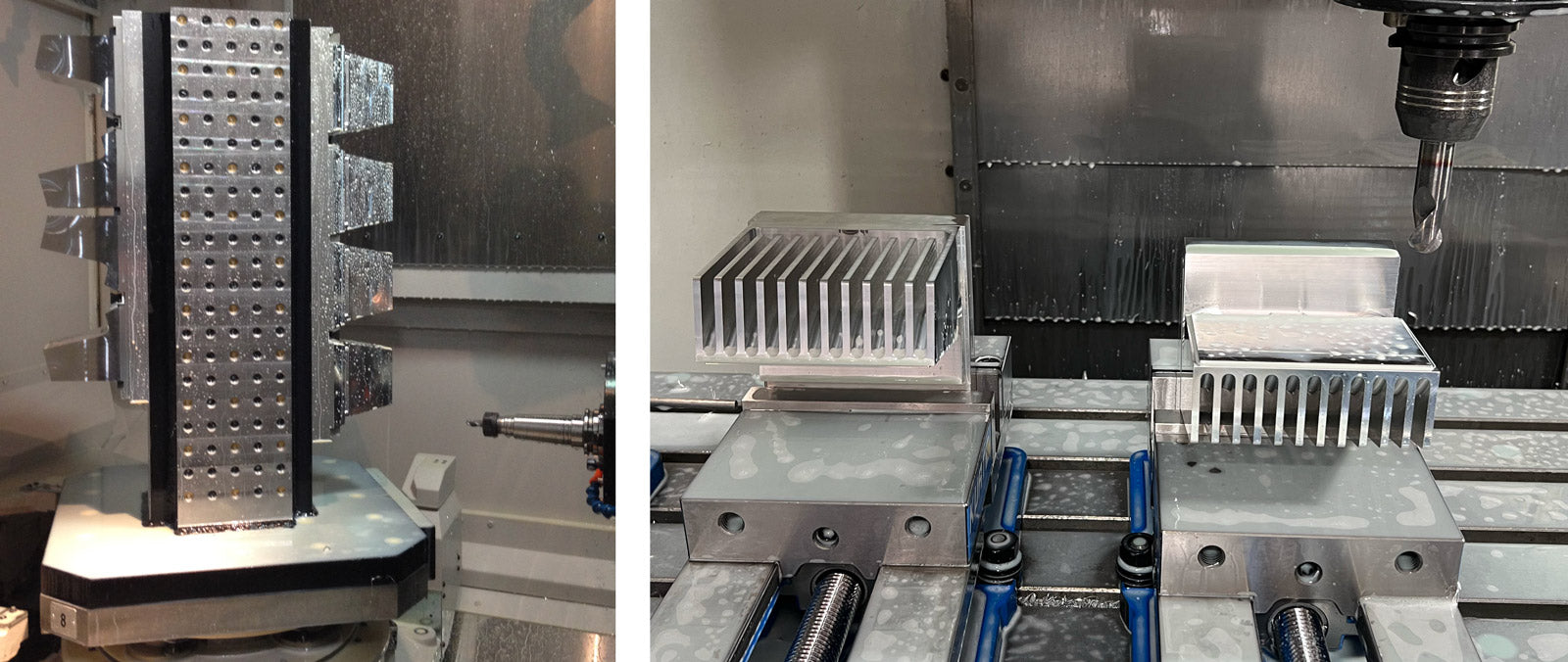

Reduce: Local

SVALT designs and manufactures locally with care in Portland, Oregon, United States. By working locally SVALT’s founder, Chad, can shorten supply chains while connecting directly with the people that make parts from the owner to operator throughout the design, development and production phases. This direct connection also extends to customer service, as Chad personally attends to customer communications and hand builds order to customer configurations. This personal care and attention to detail leads to a better product and better customer experience, as well as a mission driven company that values people over profit, and that prioritizes quality over quantity.

Reduce: Quantity

SVALT products are not mass produced off-shore to maximize per unit profits, and are instead created in small bespoke quantities with hand-finishing and hand-assembly for those that require the best performance or for those that want to have an object of substance on their desk. Since maximizing production volumes and sale profits are not the priority, SVALT can invest funds into designing innovative products and using local fabrication with a focus on sustainability; funds that would have otherwise been invested into advertising to drive higher sales volumes. Lower production volume reduces resource consumption and waste pollution for an overall lower impact.

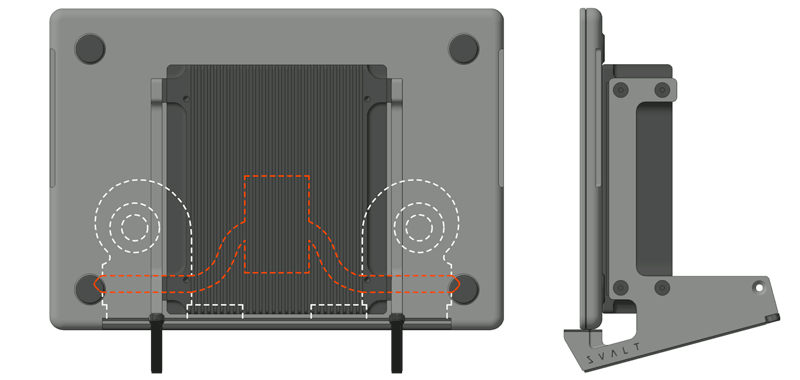

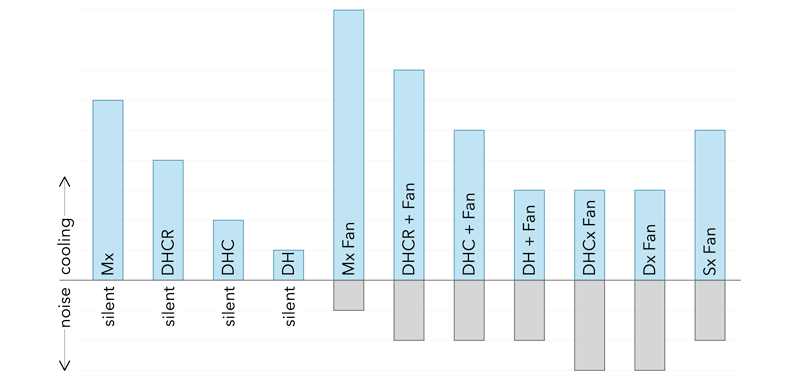

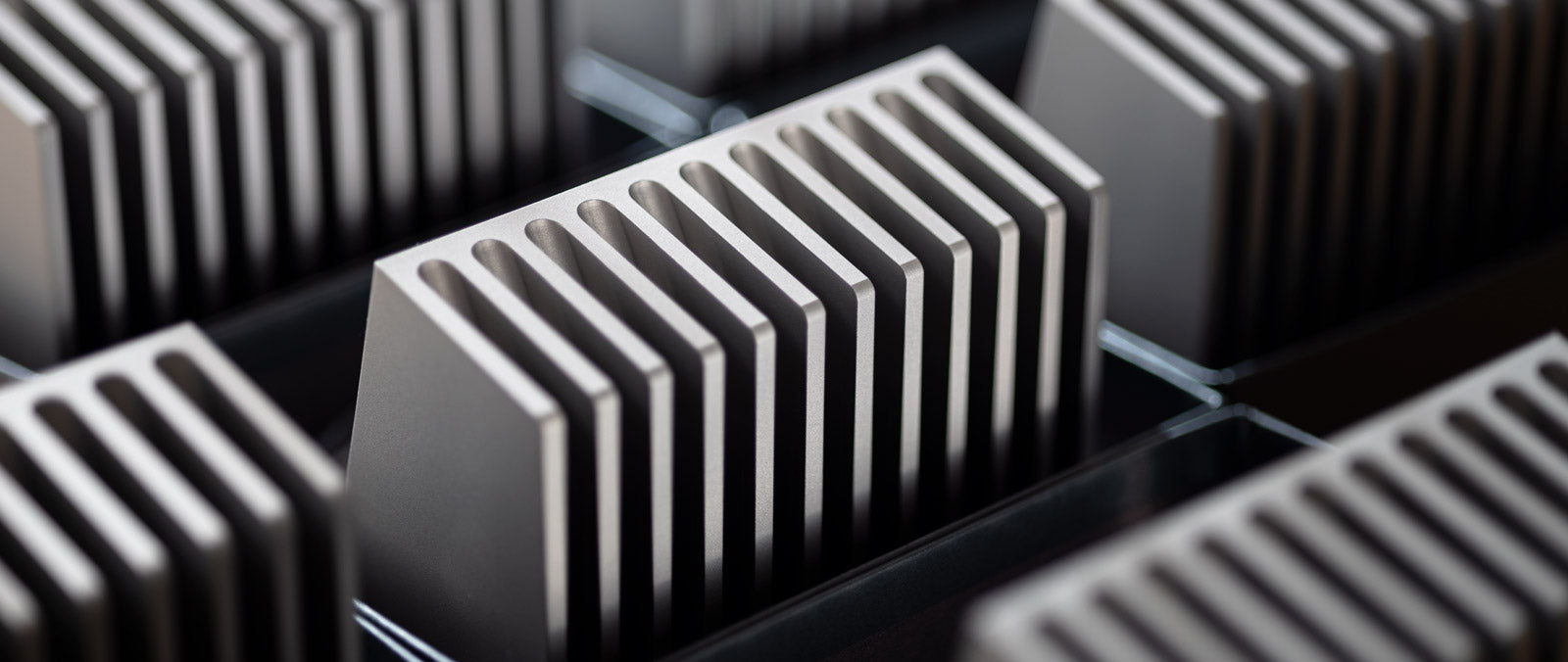

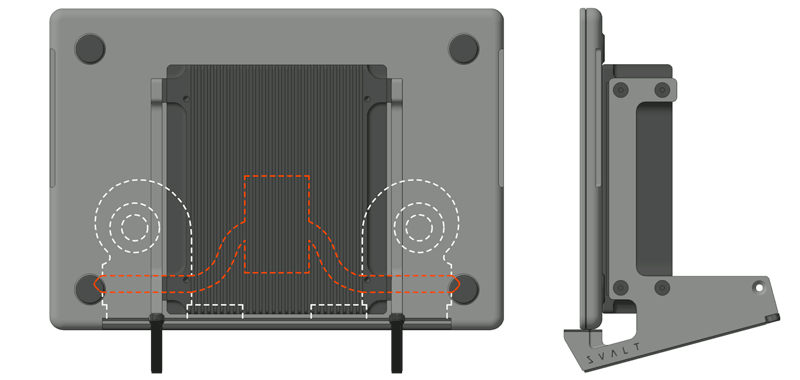

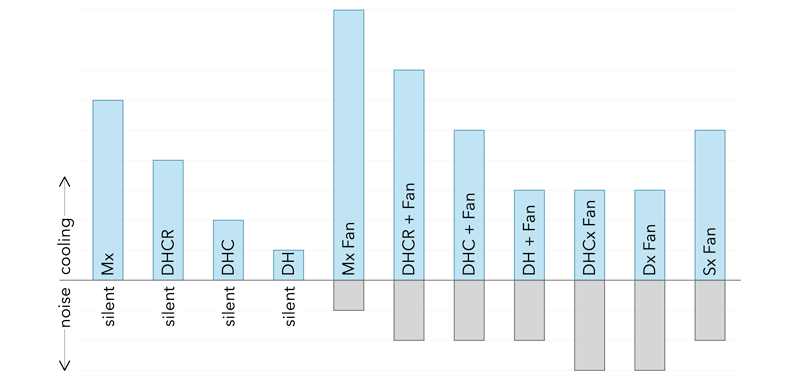

Reduce: No Power Required

SVALT offers a full range of models without fans and without the need for power, including silent conductive heatsink cooling models. In addition to these models that require no power to provide silent cooling, all of SVALT’s fan equipped models use responsive and natural passive cooling designs so that the laptop can run more efficiently even with the fan turned off. This helps to reduced energy consumption and associated pollution.

Reduce: Durability

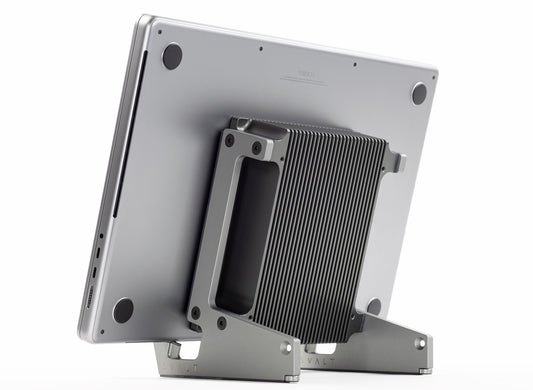

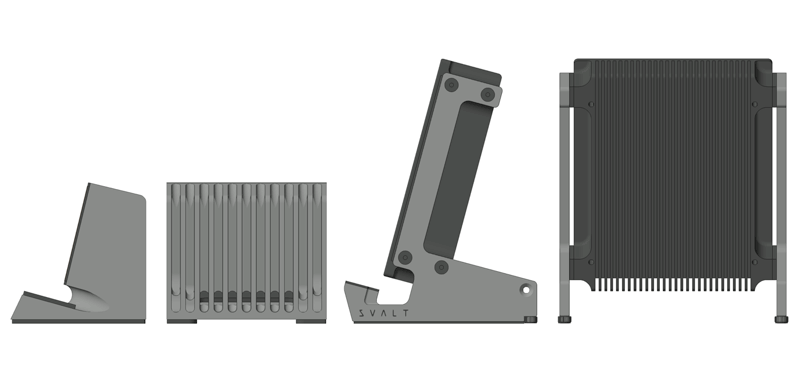

SVALT products are made primarily from durable metal construction and are designed to endure with oversized metal bolted modular assemblies that can withstand repeated re-assembly and strenuous conditions. This helps to improve product durability and increase life span, which in turn helps to reduce resource consumption and waste pollution.

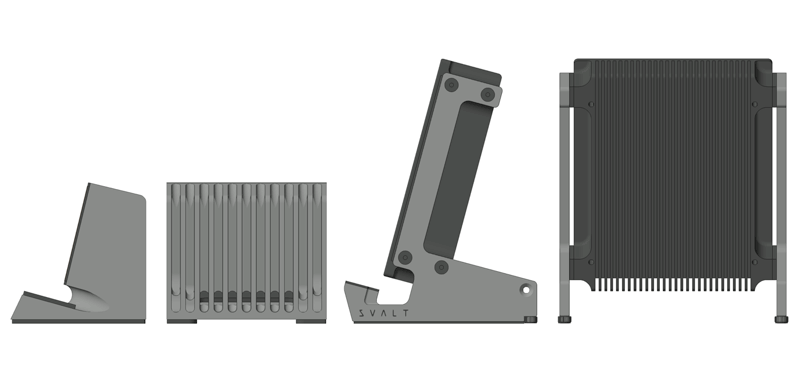

Reuse: Adaptability

SVALT products work with a wide range of devices by using a universal support design. In addition, modular designs create a reconfigurable product that accommodates a wide range of customer workstation setups. This flexible and adaptable design reuses existing resources to help increase product life span, which in turn helps to reduce resource consumption and waste pollution.

Reuse: Upgradeability

SVALT products use modular components and systems for extended use through a wide variety of replacement and upgrade options. Modular cooling systems use standard fan sizes and standard connections for additional replacement and upgrade options. These reconfigurable modular components and systems use strong bolted and quick snapped connections for repeated disassembly and reassembly. Instead of forcing customers to buy a new product, customers can upgrade components through SVALT (see upgrades page), as well as through a variety of sources of the customer’s choosing. This reuse of existing resources helps to increase product life span, which in turn helps to reduce resource consumption and waste pollution.

Reuse: Repairability

SVALT products are made to endure, are designed for right-to-repair, and ship with the tools required for disassembly, cleaning, servicing, replacing and upgrading. This reuse of existing resources helps to increase product life span, which in turn helps to reduce resource consumption and waste pollution.

Recycle: Recyclability

SVALT products primarily use metal construction with minimal plastic for easier reuse and for more viable end-of-life recycling. Anodized aluminum can be more easily re-milled and re-finished, and when it eventually reaches end-of-life-cycle, aluminum is one of the most universally recyclable materials. The new Mx product line uses cardboard and paper-based packaging with a single shipping/product box. Cardboard and other paper based packaging is among the most universally recyclable materials. This helps to recycle resources, which in turn helps to reduce resource consumption and waste pollution.

Recycle: Biodegradability

SVALT’s newest Mx product line uses a modular packaging system that is made from biodegradable cardboard and paper-based materials. The Mx product line offers each of the three models with bamboo supports that are made from FSC certified and 100% Bamboo plywood with formaldehyde-free binder. Bamboo is a strong, durable, fast-growing, rapidly-renewable, biodegradable, and more environmentally friendly material. This helps to recycle resources, which in turn helps to reduce resource consumption and waste pollution.

About Costs

Hyper-Niche and ExtremeSVALT products are designed as hyper-niche products for extreme cases where professionals require laptops to reliably perform at their peak potential. Creating these kinds of products significantly increases costs compared to products designed for mass-appeal and mass-consumption.

Local and Sustainable

SVALT products are designed for local and sustainable manufacturing with small batch production runs and orders that are hand built to a customer’s build configuration selected from a wide variety of options. Creating these kinds of products significantly increases costs compared to products designed for high-volume production with off-shore manufacturing.

Materials and Components

SVALT products are made using high-quality materials and high-end components. Making these kinds of products significantly increases costs.

First-of-Kind and Best-in-Class

SVALT products are unique patented and patent pending with innovative first-of-kind designs and best-of-class features and performance. Designing these kinds of products significantly increases costs.

About Chad

ValuesFinding joy where you can in work and life, and then sharing that joy with the world might be about the best we can do whether in easy or challenging times.

Photography

See Witness to Beauty website to learn about Chad’s photography and architecture work.

Volunteering

See The Joys of Volunteering blog post to learn about Chad’s volunteering efforts.

Featured Products

-

Cooling Dock MxDW

Regular price From $299.00 USDRegular priceUnit price / per$299.00 USDSale price From $299.00 USD -

Cooling Dock MxD

Regular price From $409.00 USDRegular priceUnit price / per$409.00 USDSale price From $409.00 USD -

Cooling Stand MxSW-hi

Regular price From $309.00 USDRegular priceUnit price / per$309.00 USDSale price From $309.00 USD -

Cooling Stand MxS-hi

Regular price From $419.00 USDRegular priceUnit price / per$419.00 USDSale price From $419.00 USD -

Cooling Stand MxSW-lo

Regular price From $289.00 USDRegular priceUnit price / per$289.00 USDSale price From $289.00 USD -

Cooling Stand MxS-lo

Regular price From $399.00 USDRegular priceUnit price / per$399.00 USDSale price From $399.00 USD -

Cooling Dock DHCR

Regular price From $279.00 USDRegular priceUnit price / per$279.00 USDSale price From $279.00 USD -

Cooling Stand Sx

Regular price From $279.00 USDRegular priceUnit price / per

Product Selection Guides

-

Compare

CompareCompare product features and specifications.

-

Laptops

LaptopsRecommended products for your laptop model.

-

Performance

PerformancePerformance testing with a variety of laptops.

Product User Guides

-

Product Upgrades

Learn about available product upgrades.

-

Right-to-Repair

Learn how to install modular components.

-

Product Setup

Learn how to setup and operate products.

Cooling Stand

“ProTools would normally have the Apple fans screaming… using it on the low setting and it's doing a beautiful job of keeping quiet… appreciate the design, skill and care that went into this product.” - L. B.

Cooling Dock

“We’re pushing them day-in and day-out. Heavy imaging, editing, rendering… Some days it was like they were literally cooking. But no more! Our Svalt D's keep them chill and lets us use them like true workstations.” - K. J.

Cooling Stand

“Respect! For sure it clearly shows your approach to design, material and sustainability. Great product. Fan noise is not audible on the low setting. Perfect! Thanks a lot for the great product.” - J. J.

Cooling Dock

“I’ve used a Hengedock for years, had no idea it was blocking one of the fans… Wish I had this cooling dock since I started using external monitors. I’m running between 13-25 cooler… benchmarks are even better.” - R. S.

Cooling Stand

“There is a noticeable help with thermals as the computer's temperature is substantially better. The fan is extremely quiet in its low setting and exceedingly efficient in its highest one. I absolutely love it.” - J. R.