DHCR DESCRIPTION

Silent Conductive Heatsink Cooling for Closed-Screen Laptops

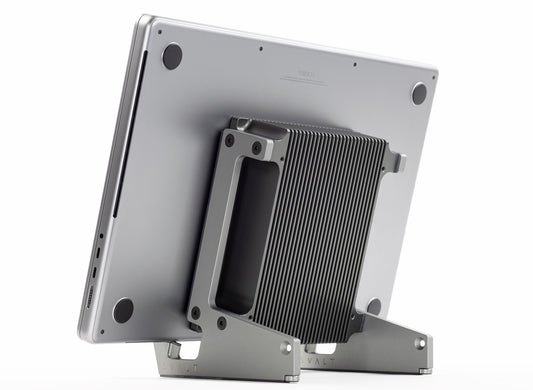

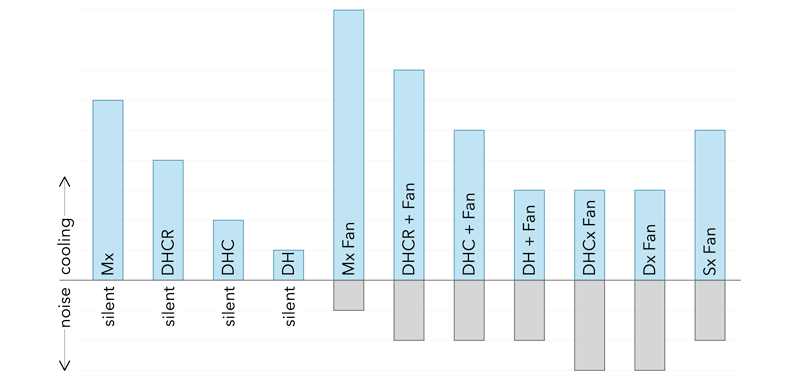

The innovative first-of-kind DHCR Cooling Dock brings best-in-class design to create the ultimate in silent thermally conductive heatsink cooling for Apple's latest laptop designs, such as the 2021+ MacBook Pro and 2022+ MacBook Air, as well as working with all current and prior Apple/Mac laptops of the last decade and most PC laptops with metal enclosures. The new 4th generation DHCR includes extensive improvements for a substantial increase in heatsink cooling efficiency with further optimization for the 2021+ MacBook Pro.

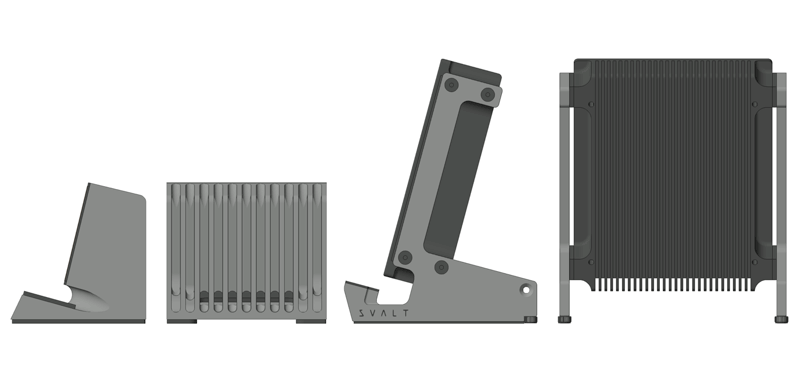

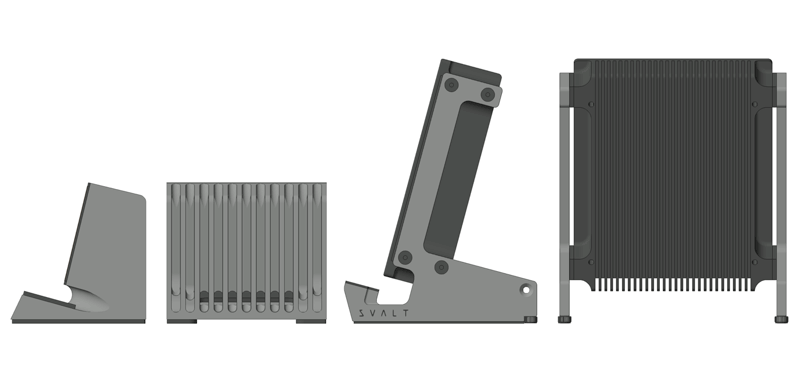

The DHCR's heatsink is carved from solid 6061 aluminum to create 12 thin cooling fins with 11 air channels cut to an incredible 2.6 inch depth by a narrow 1/4 inch diameter end mill, which provides the heatsink with an exceptionally large 143 square inches of cooling fin surface area, 188 of cooling surface area, and 233 of total surface area for optimal heatsink cooling. The DHCR’s 2.6 pound thermal mass is made from solid aluminum with interconnected cooling fins and air channels running continuously from top-to-bottom and front-to-back for improved heat transfer and improved heat flow within the heatsink mass. Compared to typical low-cost bolted-together or die-cast heatsinks, carving the DHCR’s heatsink from a solid block of aluminum requires higher precision, longer CNC milling times and much higher costs.

The machined aluminum heatsink is painstakingly finished by hand with sanding, heavy bead-blasting and a short anodize to produce a deeply-textured micro-porous non-glossy matte finish that increases the active area of the heatsink for higher radiant emissivity cooling and improved conductive cooling from both passive and active airflows. The heatsink’s extra-large laptop coupling plate is specially prepared with a fine hand sanded and polished finish that is protected from the heavy bead-blasting used on the rest of the heatsink body to produce an extra-flat and extra-smooth surface finish for improved laptop coupling and higher conductive heat transfer.

The laptop coupling plate is available with either exposed aluminum for unrestricted and maximized heat transfer through direct metal-to-metal coupling, or as an extra-cost alternative, the coupling plate is available with a special assembly of low thermal impedance materials applied over the aluminum coupling plate to add an additional layer of finish protection. Edge padding wraps around all four sides of the laptop coupling plate for corner impact protection, while the heatsink’s anodized aluminum coupling plate extends slightly beyond the top of the pads to achieve proper metal-to-metal surface contact. The 4th generation DHCR’s aluminum coupling plate edges and corners have been rounded to remove sharp edges for direct metal-to-metal contact. Direct heatsink coupling is a standard configuration with lower cost and short build lead times.

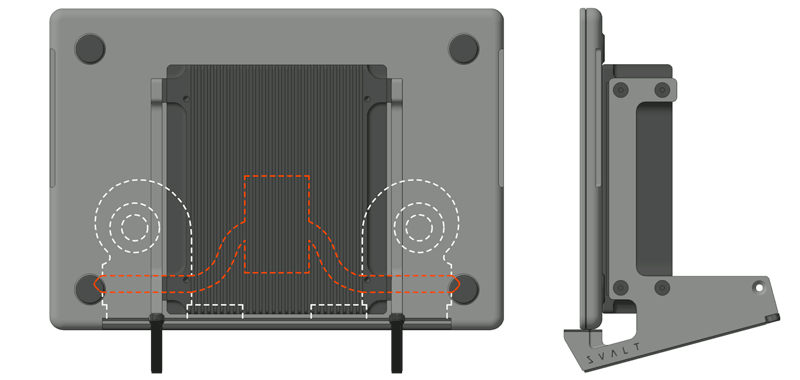

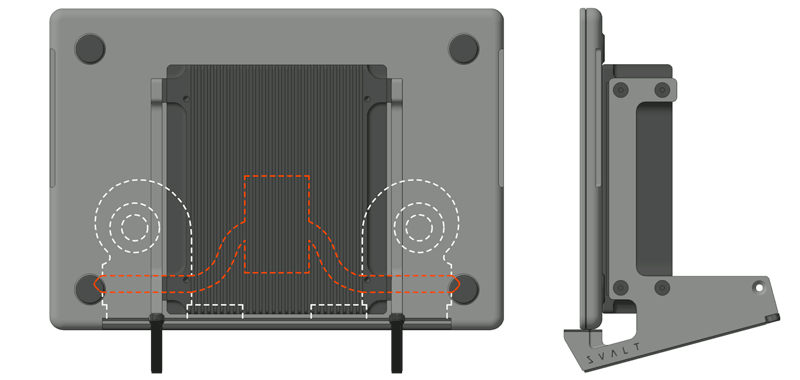

The DHCR not only achieves high levels of silent heatsink cooling efficiency, but uses an integrative design approach to achieve optimal cooling performance with the latest 2021+ MacBook Pro. The DHCR’s heatsink is positioned at the laptop processor location to extract more heat directly from the heat source. The overall support cradle width, the heatsink coupling plate width, and the air channel locations match the laptop’s processor and built-in cooling system layout. The heatsink’s numerous vertical cooling fin air channels extend through the heatsink mass to become through-holes that guide cooling airflow into a front horizontal air channel with curving ends. This cooling airflow supplies the laptop’s center intake vent with cool air and flushes out hot exhaust air from the laptop. The heatsink’s integral design supports more efficient operation of the laptop’s built-in cooling system and helps the laptop maintain peak performance potential.

The DHCR’s heatsink design facilitates silent passive airflow cooling as well as accelerated active airflow cooling from the optional Fx Cooling Fan. The Fx boosts heatsink cooling, flushes out more hot air, and drives cooling airflow into the center intake vent on the 2021+ MacBook Pro for direct internal processor cooling. The heatsink’s front horizontal channel uses a smaller size to concentrate airflow along the laptop’s bottom screen-hinge edge, while numerous thru-hole air channels extend below the laptop’s center intake vent and then angle up to guide cooling airflow into the vent.

The DHCR includes three new heatsink performance pads for maximum cooling performance with a 2021+ MacBook Pro and/or a Fx Cooling Fan. New performance bottom pads feature 1/8” thickness to create a large underside open air channel for improved heatsink cooling. New performance laptop support pad features 1/8” thickness with a center cutout matching the heatsink’s through-holes for improved cooling airflow into a 2021+ MacBook Pro’s central air intake vent, and features side extensions into the horizontal channel’s curving ends. Both of the new 1/8” thick performance pads are designed to work in conjunction with the new performance insulating side pads that protect the heatsink from a 2021+ MacBook Pro’s hot air exhaust vents.

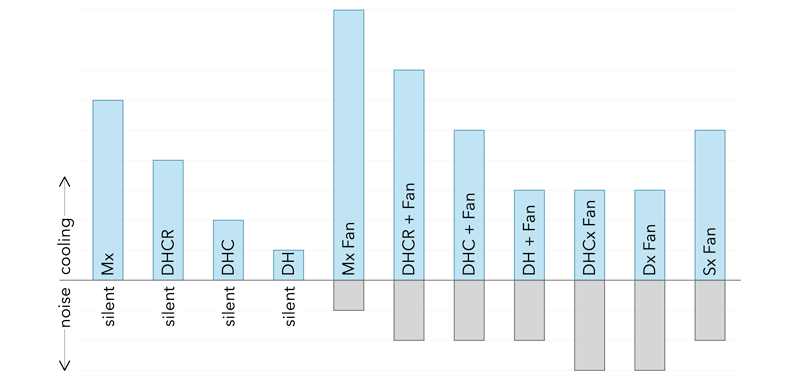

The DHCR and Fx utilize a separated fan design strategy instead of using a built-in fan as this allows the separated fan to be positioned outside of a constraining enclosure so that the fan may more freely operate with optimal airflow efficiency, which in turn allows the fan to generate more airflow with less noise. The separated fan design also allows the heatsink to be as large as possible with the most thermal mass and surface area, which leads to increased heatsink cooling capacity. The combination of increased cooling airflow and higher heatsink cooling capacity results in a significant improvement in overall cooling performance.

The DHCR and all Cooling Dock models work with the laptop operating in closed-screen clamshell mode while connected to one or more external monitors, external keyboard/mouse and power supply. All Cooling Dock models also feature a unique and stable leaning support for easy clamshell setup while the laptop remains connected to cables and safely in a padded cradle with adjustable/replaceable laptop retention pads (extra pads included for future setups).

All SVALT cooling systems use modular bolted / snapped assemblies and ship with the tools required for right-to-repair servicing, exchanging, upgrading and extending product life span.

SVALT designs innovative patented and/or patent pending products made locally in the Pacific Northwest with a focus on sustainability, and use solid aluminum for enduring metal construction.

Featured Products

-

Cooling Dock MxDW

Regular price From $309.00 USDRegular priceUnit price / per -

Cooling Dock MxD

Regular price From $409.00 USDRegular priceUnit price / per -

Cooling Stand MxSW-hi

Regular price From $319.00 USDRegular priceUnit price / per -

Cooling Stand MxS-hi

Regular price From $419.00 USDRegular priceUnit price / per -

Cooling Stand MxSW-lo

Regular price From $299.00 USDRegular priceUnit price / per -

Cooling Stand MxS-lo

Regular price From $399.00 USDRegular priceUnit price / per -

Cooling Stand Sx

Regular price From $279.00 USDRegular priceUnit price / per -

Cooling Stand SxM

Regular price From $279.00 USDRegular priceUnit price / per

Product Selection Guides

-

Compare

CompareCompare product features and specifications.

-

Laptops

LaptopsRecommended products for your laptop model.

-

Performance

PerformancePerformance testing with a variety of laptops.

Product User Guides

-

Product Upgrades

Learn about available product upgrades.

-

Right-to-Repair

Learn how to install modular components.

-

Product Setup

Learn how to setup and operate products.

Cooling Stand

“ProTools would normally have the Apple fans screaming… using it on the low setting and it's doing a beautiful job of keeping quiet… appreciate the design, skill and care that went into this product.” - L. B.

Cooling Dock

“We’re pushing them day-in and day-out. Heavy imaging, editing, rendering… Some days it was like they were literally cooking. But no more! Our Svalt D's keep them chill and lets us use them like true workstations.” - K. J.

Cooling Stand

“Respect! For sure it clearly shows your approach to design, material and sustainability. Great product. Fan noise is not audible on the low setting. Perfect! Thanks a lot for the great product.” - J. J.

Cooling Dock

“I’ve used a Hengedock for years, had no idea it was blocking one of the fans… Wish I had this cooling dock since I started using external monitors. I’m running between 13-25 cooler… benchmarks are even better.” - R. S.

Cooling Stand

“There is a noticeable help with thermals as the computer's temperature is substantially better. The fan is extremely quiet in its low setting and exceedingly efficient in its highest one. I absolutely love it.” - J. R.